Using flameless combustion technology, UTOC significantly reduces harmful emissions and the need for landfills.

UTOC

Next Generation Garbage Recycling

Disruptive Technology that will dramatically change the way we handle waste on our planet.

The UTOC (Ultimate Thermal Organics Converter) has been operating since the fall of 2021 near High Bluff, Manitoba, CANADA where numerous groups from the construction industry, the agricultural industry, the recycling industry, as well as municipal leaders and Provincial MLA’s have visited.

“Thanks for the demo yesterday. Generated a lot of ideas and discussion among us on the drive there and back... [the] next plan is to bring this forward to our regional manager, and discuss the next steps in how we can support more commercialization.”

PCL Construction

Proven Technology

The simple radiant energy organics vaporization and high temperature flameless oxidation of vapours has been repeatedly demonstrated and proven.

VOsPS Inc (pronounced “VOPS”), incorporated in the province of Manitoba August 21, 2017, is a “Value Optimized sustainable Planet Solutions” consultant and the global supplier of UTOC systems.

Experienced Staff

Key VOsPS personnel have collectively more than 250 years experience in international trade, UTOC technology customization & optimization, Engineering, Procurement & Construction, systems automation & commissioning, and government relations.

Dependable Manufacturing

ISO 9001:2008 certified, our UTOC systems fabricator has manufacturing plants in Canada and the USA, with more than 40 years experience in product structural & mechanical systems manufacturing and installation.

UTOC systems are fully scalable, optimized, and ready to meet any demand.

How UTOC works

When people come to see the UTOC in action at our demonstration site, the features they first notice is the system is quiet, there's no smoke and the only fuel it needs is garbage. One of our guests, after watching it for a while, asked when we were going to start it up to which we replied, "it's been running since you arrived."

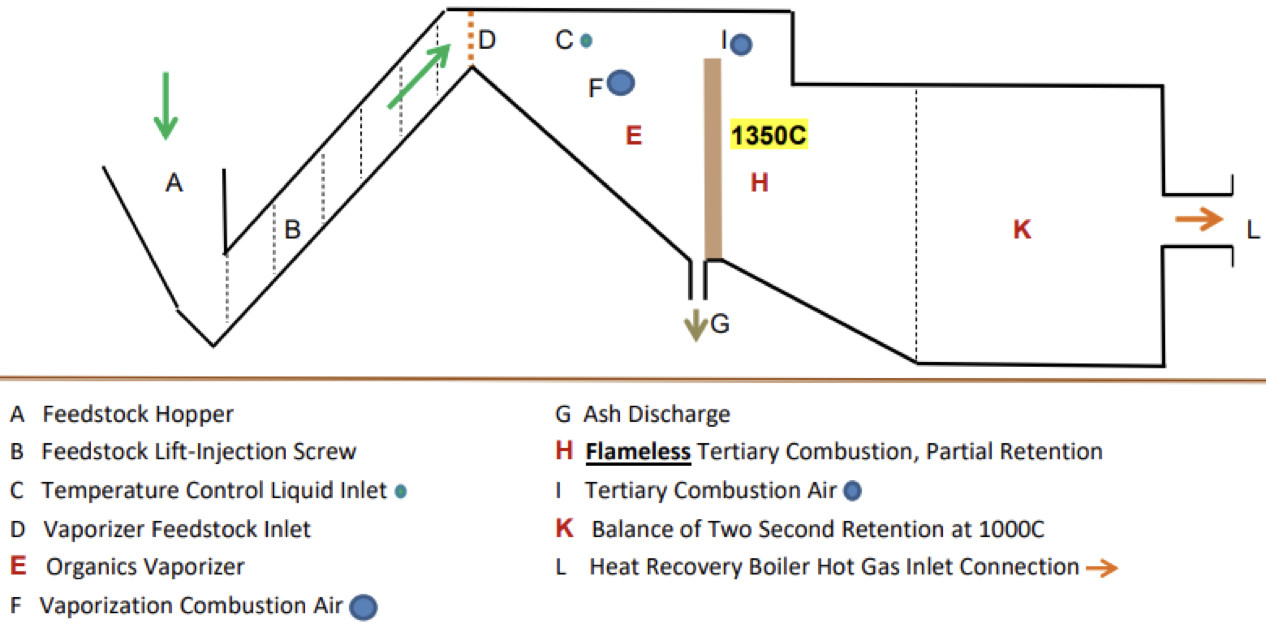

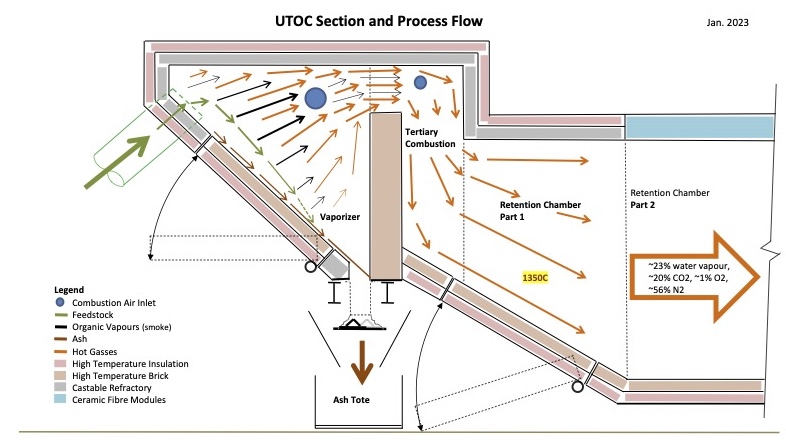

The Vaporizer

The diagram above shows the three chambers of the UTOC. The first chamber is the vaporizer where organic waste, either shredded solids, liquids or gases, enters via the feedstock auger or liquid/gas injection port. UTOC is designed to run 24/7, but when we first start it up we use propane for the first 24 hours to heat this chamber. After startup, the UTOC requires no fuel other than the garbage itself. The fireball above the sloped surface radiates heat, up to 1,350°C, onto feedstock slowly flowing down the slope vaporizing organic waste into smoke and ash. The resulting smoke burns as clean as natural gas, so we inject just enough oxygen to burn up to 90% of the smoke, regulating the vaporizer temperature .

Vaporizer temperature is automatically regulated and will change according to the energy content of the incoming material; if the material is highly volatile like oil, lower temperatures are needed than if the material is less volatile like wet garbage. To prevent the chamber exceeding 1,350°C, we inject waste liquids (shown as "Temperature Control Liquids" in the infographic) to cool it down.

Already in this first chamber, the organic waste is vaporized into smoke of which 90% is combusted while the remaining inorganic fraction is turned to sterile ash as it slides down the slope towards the ash tote.

The diagram above shows the three chambers of the UTOC. The first chamber is the vaporizer where organic waste, either shredded solids, liquids or gases, enters via the feedstock auger or liquid/gas injection port. UTOC is designed to run 24/7, but when we first start it up we use propane for the first 24 hours to heat this chamber. After startup, the UTOC requires no fuel other than the garbage itself. The fireball above the sloped surface radiates heat, up to 1,350°C, onto feedstock slowly flowing down the slope vaporizing organic waste into smoke and ash. The resulting smoke burns as clean as natural gas, so we inject just enough oxygen to burn up to 90% of the smoke, regulating the vaporizer temperature .

Vaporizer temperature is automatically regulated and will change according to the energy content of the incoming material; if the material is highly volatile like oil, lower temperatures are needed than if the material is less volatile like wet garbage. To prevent the chamber exceeding 1,350°C, we inject waste liquids (shown as "Temperature Control Liquids" in the infographic) to cool it down.

Already in this first chamber, the organic waste is vaporized into smoke of which 90% is combusted while the remaining inorganic fraction is turned to sterile ash as it slides down the slope towards the ash tote.

The Tertiary Chamber

The remaining 10% of the smoke now enters the next chamber which burns at a constant 1,350°C with just a little more oxygen than is needed to ensure the smoke is completely burned. All the smoke is now completely combusted leaving only clean hot gases with unprecedentedly low emissions that, so far as third party testing shows, require no further cleaning to meet regulatory emission limits.

The Retention Chamber

We've consulted with the Canadian Food Inspection Agency in creating the UTOC. To maximize the destruction of pathogens, like the BSE prion, the most difficult to destroy ("mad cow disease"), they require that gases be held at 850°C for two seconds. That's the only function of the retention chamber which ranges between 900°C and 1,320°C, exceeding CFIA requirements.

The remaining 10% of the smoke now enters the next chamber which burns at a constant 1,350°C with just a little more oxygen than is needed to ensure the smoke is completely burned. All the smoke is now completely combusted leaving only clean hot gases with unprecedentedly low emissions that, so far as third party testing shows, require no further cleaning to meet regulatory emission limits.

The Retention Chamber

We've consulted with the Canadian Food Inspection Agency in creating the UTOC. To maximize the destruction of pathogens, like the BSE prion, the most difficult to destroy ("mad cow disease"), they require that gases be held at 850°C for two seconds. That's the only function of the retention chamber which ranges between 900°C and 1,320°C, exceeding CFIA requirements.

UTOC Safety Features

UTOC is safe to operate. There are numerous safety features that are automatically triggered should anything ever go wrong.

Sensors, heat-sensitive fuses and air dampers at various locations in the UTOC, system ensure temperatures don't exceed design limits. If there is a problem, the fan stops causing the feedstock auger to stop and the emergency vent stack to open and flare off remaining combustible vapors.

A manual emergency shutoff achieves the same result.

The Induction Fan, the round green component on the far right at the base of the stack in the picture below, is the heart of the UTOC. It draws air through the entire system keeping it at a slight negative pressure, maintaining UTOC energy output at manually input or automatically variable rates between 10% and 100% of system design capacity. The negative pressure keeps the entire system safe; you can open a portal on the side of the UTOC for inspection without fear of flare-outs singeing your eyebrows because air is continually being drawn INTO the UTOC.

The high temperature envelope (brown colored component) is lined to prevent the surface temperature exceeding ~120°C when the internal temperature is 1,400°C.

Burn back down the feedstock injection auger is prevented by a heat-sensitive fuse that opens a bottom drop door, emptying material from the auger to create a fire break, allowing cooling air into and up the emergency vent stack. If needed, a water valve is also activated to wet feedstock in the auger.

UTOC can be operated by an entry level worker with UTOC training.

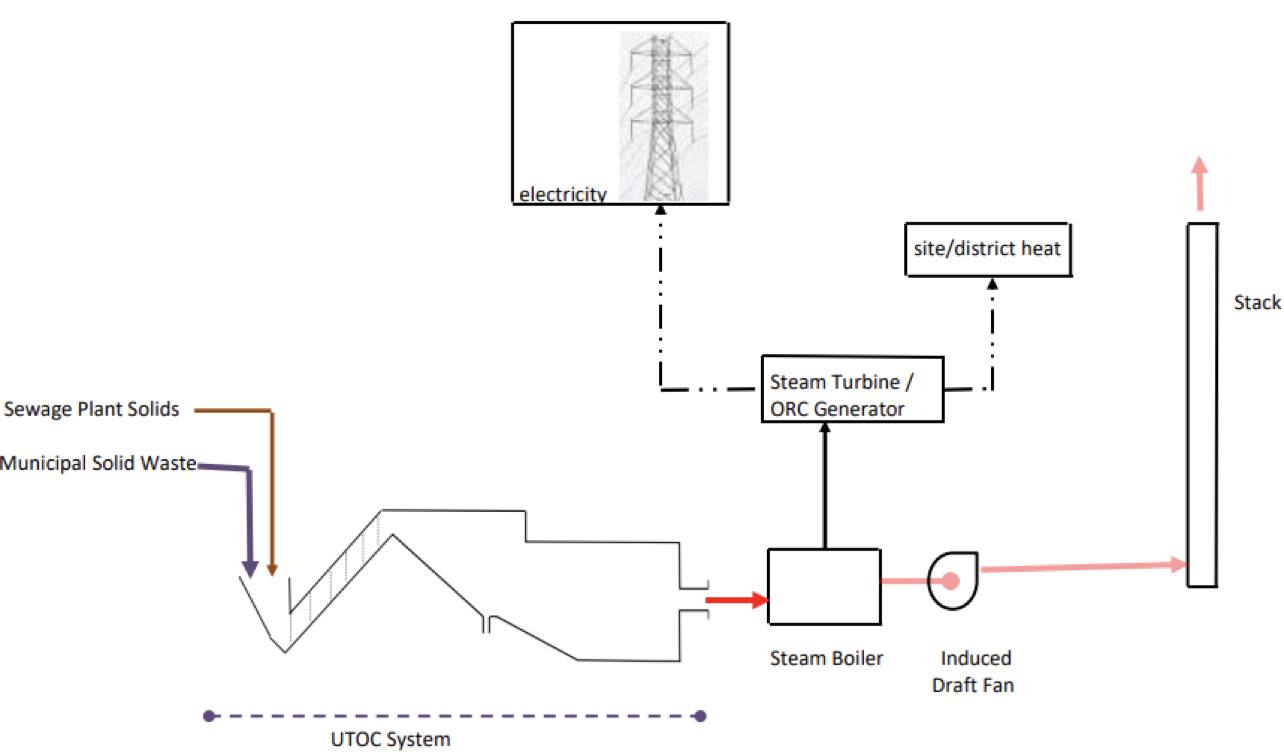

A UTOC Energy from Waste Plant

With feedstock of approximately 5.5 tonnes per day of Municipal Solid Waste and 4,500 litres per day of wastewater, approximately 880 kW/hour of clean energy is produced. That capacity recycles waste from a typical community of approximately 2,700 people.